Pixim Digital Pixel System ® Technology Backgrounder

CCD

CCD sensor technology has been dominant in image applications since the technology debuted in the late 1960’s. However, its analog design is based on a “bucket brigade architecture” and requires a non-standard fabrication process that is both complicated and costly to optimize. It is difficult for commercially viable sensor arrays to integrate analog-to-digital conversion (ADC) for digital processing onto CCDs, or to customize them by adding logic blocks to the chip for specific applications. Their high voltage (+12 to +20 Volts) and power requirements shorten battery life and limit their applicability in small form factor, portable devices. Moreover, the need to add external supporting components (including analog front end, timing circuit, reference voltage, correlated double sampling, mechanical shutter and RAM) results in large printed circuit board real-estate requirements, contrary to the trend of miniaturization in weight and size.

CMOS APS

CMOS sensors were developed in the early 1980’s. Passive pixel sensor (PPS) image sensors were the first products in this family to come to market. The large feature sizes available in existing CMOS technology allowed only a single transistor and three interconnecting lines for each pixel. The speed and signal-to-noise-ratio of PPS was significantly lower than that of CCD sensors. In the 1990s, APS technology added an amplifier to each pixel. This increased sensor speed and improved the signal-to-noise-ratio, providing a big advantage over PPS sensors. When deep sub-micron CMOS technologies and micro-lenses appeared, APS became the alternative sensor technology. Its low power consumption and near-standard manufacturing process made it a competitor to CCD sensors for certain applications. However, APS technology has inherent problems. Due to process variations that create nonuniformities in the column level ADCs and in-pixel amplifiers, large fixed pattern noise (FPN) at high resolutions typically yields limited sensitivity, less than is required for many applications, including security and the film industry. Human eyes are particularly sensitive to image edges, and the column-level ADCs amplify this noise.

Pixim DPS Image Sensing Technology

Because DPS technology integrates the ADC into the pixel, it can be manufactured using leading edge semiconductor processes. The pixel array has significantly higher noise immunity than APS sensors because DPS technology employs a digital readout from each pixel (see Figure 5). Additional image processing and camera functions implemented by Pixim provide a complete imaging solution in high-volume, commercially available chipsets. DPS image systems integrate sensing, memory and processing functions into two chips. This is especially important for imaging systems that require significant processing, where quality of output is crucial, and where small size, low power and portability are important.

Until now, analog-to-digital conversion could only be integrated at the chip or column level. Both approaches are common in APS sensor solutions. For the chip-level approach, a single conventional high-speed ADC is integrated with the sensor. For the column-level approach, one or more columns of the pixel array has a dedicated ADC. The ADCs are operated in parallel and, therefore, low-to-medium speed conversion techniques must be used (e.g., single-slope, algorithmic, successive approximation, or oversampling). By having separate ADCs for each pixel operating in parallel, the ADCs can operate at very low speed, operating at a few thousand samples per second. This lessens noise and reduces power requirements. The large bit stream used to read the ADCs is supported by on-chip RAM. These features enable much faster and more accurate readout characteristics. The DPS sensor consists of an m * n digital pixel sensor array, ADCs and RAM. A separate chip incorporates digital signal processing (DSP), and I/O. The sensor core is powered by a single low-voltage power supply. Manufacturing is simpler than for CCDs and great e r miniaturization is realized. These advantages will continue to increase in the future in accordance with Moore’s Law. The DPS pixel-level ADC architecture permits the use of low-speed conversion; the ADCs operate close to where the photodiode signals are generated. This optimizes signal-to-noise ratio (SNR) and power consumption beyond any sensors currently available. The large number of independent, small ADCs significantly reduces noticeable fixed pattern noise problems commonly associated with the column-level ADC variation on APS sensors. Finally, because pixel signals are available to ADCs at all times, the number and timing of images—as well as the number of bits from each image—can be freely chosen. This offers important advantages, such as the ability to optimize the image capture and processing to the scene characteristics. All of these features have been implemented in Pixim DPS systems.

Pixim’s patented Digital Pixel System (DPS) technology marks a fundamental breakthrough in imaging technology. Building upon technology developed at Stanford University in the 1990s, Pixim has created an image capture and processing system that provides high-quality pictures with enhanced dynamic range. Greater dynamic range significantly improves image quality in scenes consisting of both bright and dark areas. The DPS invention

The core invention in DPS is the inclusion of an analogto- digital converter (ADC) within each pixel of the image sensor. The ADC translates the light signal into a digital value at the immediate point of capture, thus minimizing signal degradation and cross-talk in the array and allowing for greater noise reduction methods. Once the data is captured in a digital format, a variety of digital signal processing techniques are used for optimal image reproduction.

Pixim multi-sample technology

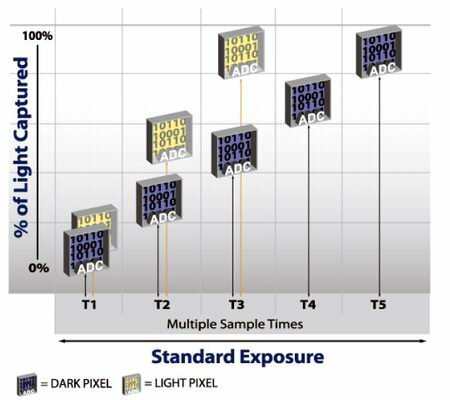

Pixim’s DPS technology uses a technique known as “multi-sampling” to gather the information to achieve unmatched image quality and high dynamic range. Each pixel is independently sampled non-destructively multiple times in a single capture frame (which in video is typically 50 or 60 times per second). The imaging system determines the optimal time to sample and store the pixel information before the pixel is saturated and can no longer hold additional charge. In the graphic on the left, the light pixel is saved at time T3, the latest sample time before it saturates at 100 percent. The dark pixel builds up charge more slowly and uses additional time until it is sampled and stored at T5. The stored values of information (intensity, time, noise offset) captured at each pixel are then processed in parallel and converted into high-quality images. In contrast, other technologies typically set one exposure time for the frame and sample each pixel at that time – resulting in images with some pixels that are underexposed (too dark) and some that are overexposed (too bright).

EYE and BRAIN

Pixim’s first product based on DPS technology, the D2000 Video Imaging System, like the latest generation, D2500, are comprised of a digital image sensor and a digital image processor. The digital image sensor and digital image processor function much like the eyes and brain in humans, with twoway real-time interactivity to capture the highest quality image possible. Just as the brain of a person walking into a dark room instructs the eyes to open the pupil to allow in more light, the digital image processor loads new code into the sensor to alter not only exposure times but the actual image capture algorithms. The result: the best possible picture given the specific image characteristics and lighting conditions.

Every pixel is A Camera

Because each pixel has its own analog-to-digital converter and the information generated is captured and processed independently, each pixel in effect acts as its own camera. The exposure time for each pixel is adjusted to handle the unique lighting conditions at that pixel location in the image sensor array. A product built with the Digital Pixel System platform essentially has hundreds of thousands of individual cameras, each of which produces the best image possible. These images are then combined to create a high quality video frame or picture.

As imaging technology continues to migrate toward totally digital systems, Pixim’s Digital Pixel System technology will provide the foundation for image capture and image processing for the highest quality video and still cameras.

CCD

Pixim